Please contact your authorized Shunyata Research dealer or regional distributor for pricing.

Shunyata Research invests heavily in research and development, affording even our least expensive products the quality and performance that have made our reference products worldwide standard bearers. Venom HC v2 power cords are engineered to deliver on Shunyata’s promise of exceptional value and performance.

The Venom HC v2 is the descendant of the Venom-3 which The Absolute Sound voted as “One of the 30 Best Values in all of Audio”. The Venom HC v2 comes equipped with 10 gauge OFE power conductors for excellent current delivery. The fluorocarbon dielectrics are usually only found on much more expensive power cables providing clarity and excellent low level resolution. And the Venom HC’s pure copper contacts are unheard of at this price point.

APPLICATIONS

The Venom HC v2 with its 10 gauge conductors is highly recommended for use with Shunyata Research’s power conditioners and for high power power amplifiers.

Other cables to consider: For even better performance with CD players, DACs and other source components we highly recommend Shunyata Research’s Gamma NR noise reduction power cord. The Venom V14 NR power cable is ideal for devices that use very noisy switched mode power supplies (SMPS) including computer peripherals, music-servers, NAS arrays, routers, switches, monitors, clocks, up-samplers, digital transports, wall warts, and power bricks.

For custom length Venom HC cables, please visit the Venom HC Custom page.

TECHNOLOGY

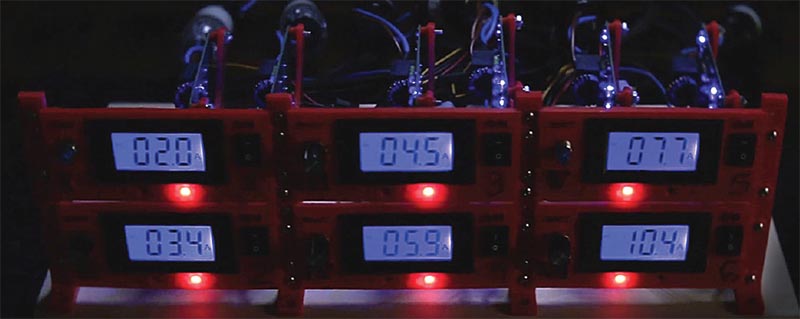

DYNAMIC TRANSIENT CURRENT DELIVERY

DTCD™ Analysis is a technique that measures instantaneous current through low impedance electrical conductors and contacts. Shunyata Research uses it to optimize the design, specification and construction of parts and materials to ensure maximum current delivery performance. Each part, conductor, noise circuit and material allows for maximum throughput of instantaneous current.

Listeners will experience earth-shaking low-frequency performance from even the highest-current amplifiers as well as dynamic contrasts unheard of outside of a live event. More than any other design parameter, Shunyata Research’s skill in eliminating resistance and maximizing peak-current delivery is unmatched.

OFE Alloy 101

Shunyata Research uses only the highest purity of copper available for the production of its wire products. OFE Alloy 101 or C10100 is the highest grade of copper with a minimum 99.99% purity and a conductivity rating of 101% IACS. OFE stands for oxygen-free electrolytic and supersedes the term OFHC (oxygen-free high conductivity). C10100 is the only grade of copper that comes with a written certification of purity.

Certified by ASTM F68 C10100

Fluorocarbon dielectrics are usually only found in wire used in the aerospace industry, satellites and only the most expensive audiophile cabling. It has special electrical characteristics; very low dielectric absorption, high dielectric strength and exceptional heat resistance. When used in audio and power cables is reduces the perception of dynamic compression and it improves sonic low-level resolution and clarity.

Crystal clear transient detail.

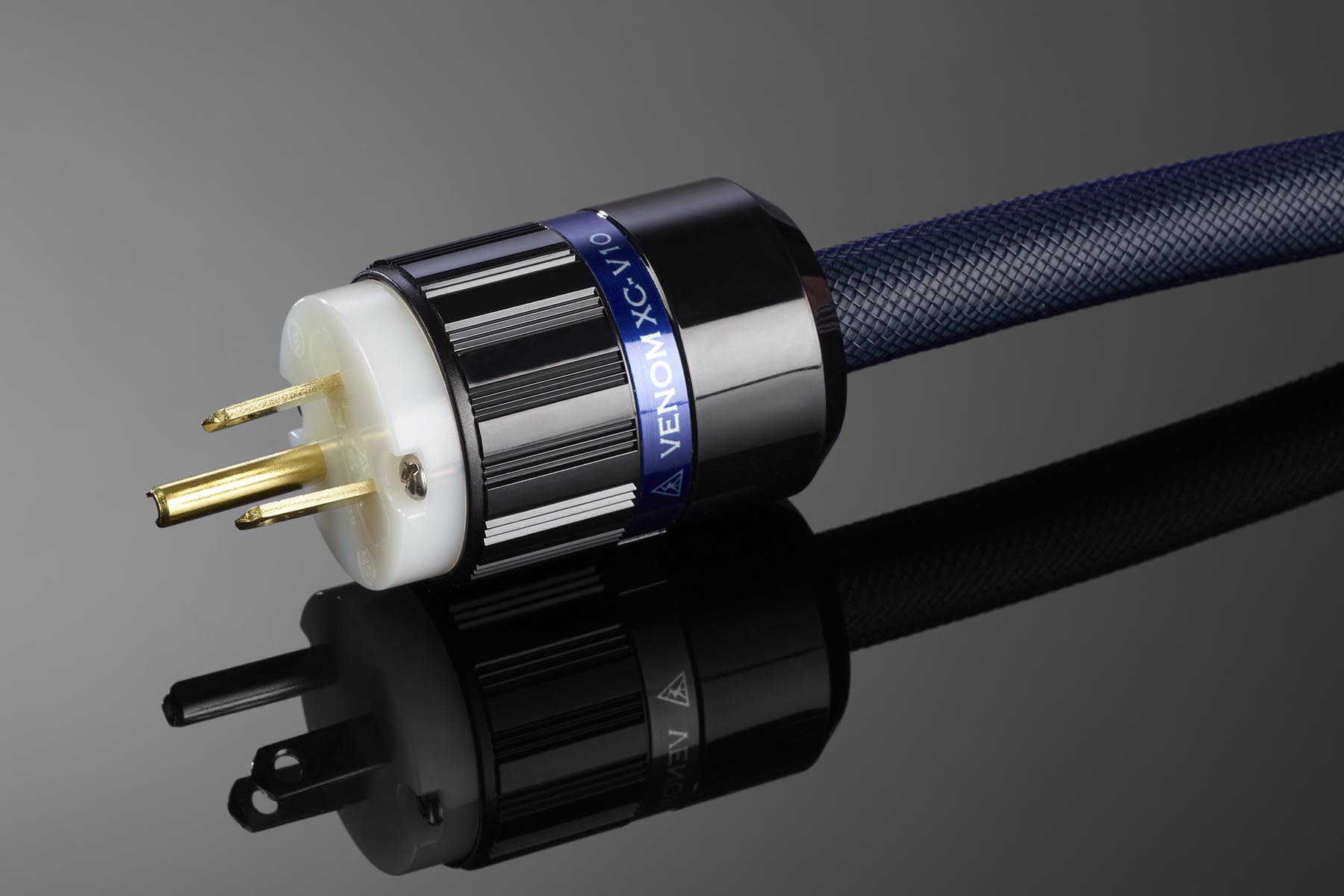

Audiophile Grade Connectors

Shunyata Research audiophile-grade connectors are made from a high-grade brass-copper-zinc alloy that can accept the very large 08 gauge conductors. The polycarbonate head-shells provide a lifetime of longevity.

Hermetically Sealed

The connectors are hermetically sealed with an electrically inert compound that protects the contacts and wires from corrosion. The compound also ensures that the wires cannot become loose, fray or pull out from the head shell. This guarantees a lifetime of reliable performance that does not degrade over time.

KPIP™ PROCESSING

Shunyata Research’s proprietary Kinetic Phase Inversion Process includes four days of continuous KPIP™ processing to dramatically reduce burn-in time and significantly improve sonic performance, delivering a relaxed and life-like presentation.

SPECIFICATIONS

|

Conductors: Connectors: |

Safety Assurance: Dimensions: Length: 1.75 meters (C19) |

OUR ASSURANCES

RELIABILITY

Over more than 2 decades, the reliability and durability of Shunyata Research products has become a legendary attribute of the brand. Shunyata products are completely non-reactive and run cool to the touch. They do not hum, vibrate, buzz, or generate heat and do not require any ventilation. Despite heavy-use applications in studios, medical labs, and home environments, Shunyata Research products maintain an almost zero failure rate.

QUALITY

In an era of products that are mass-produced, Shunyata Research invests in training career craftsman who build our products by hand at our factory in Poulsbo, Washington. The exceptional fit, finish, and attention to detail has become a hallmark trait of Shunyata Research products going back to its inception in 1998. Shunyata Research has been building some of the finest power and cable products in the industry for more than twenty years. The commitment to building durable products that are designed to last a lifetime elevates our products to the top of their class.

SAFETY

Safety and quality control is job one at Shunyata Research. Before anything leaves the factory, we test each and every product thoroughly and carefully for safety and quality. This explains the long-term success of Shunyata Research products in the professional recording, medical, scientific, and consumer industries. Shunyata Research’s impeccable product safety and reliability track record for the past 23 years speaks for itself.

NO HUM — NO BUZZ — NO HEAT

LIMITED LIFETIME WARRANTY