DENALI 6000/T

NO LONGER AVAILABLE

Product is no longer available.

No Hum No Buzz No Heat

“I’ve been using the DENALI 6000 in a small set up — Wilson Sasha with Dan D’Agostino integrated. All I can say is I want every one of my customers to have one. STUNNING!!!”

– Maier Shadi, The Audio Salon, Santa Monica.

The DENALI 6000/T represents the vanguard for a series of products that have attained legendary status in the arenas of power-conditioning technology, customized design, performance and value. The DENALI 6000/T’s unique Tower form factor includes an integrated base, stainless-steel feet and cable-cradle support system, making it the most elegant easy-to-place product in its category. Internally, the 6000/T features custom-manufactured solid-copper outlets, patented QR/BB™ modules for high-current applications and medical-grade filters that reduce noise to an astounding – 60dB at 1 mHz, while far more costly products reduce noise by less than half that. In an era where five-figure price-tags have become commonplace for power-conditioners, the DENALI 6000/T delivers state-of-the-art performance, unique technology and the finest in out-side-the-box craftsmanship for a fraction of the price.

Upgrade to v2

This upgrade converts existing Denali 6000/T units to version 2 and will include internal upgrades only (no external changes). Internally, the updated 6000/T v2 is an almost complete rebuild!

Denali 6000/T v2 Upgrade Features

• 6 independent zones of isolation (all 6 outlets are isolated from one another)

• 6 independent high current outlets

• Includes significantly improved versions of the QRBB, NIC and CCI modules

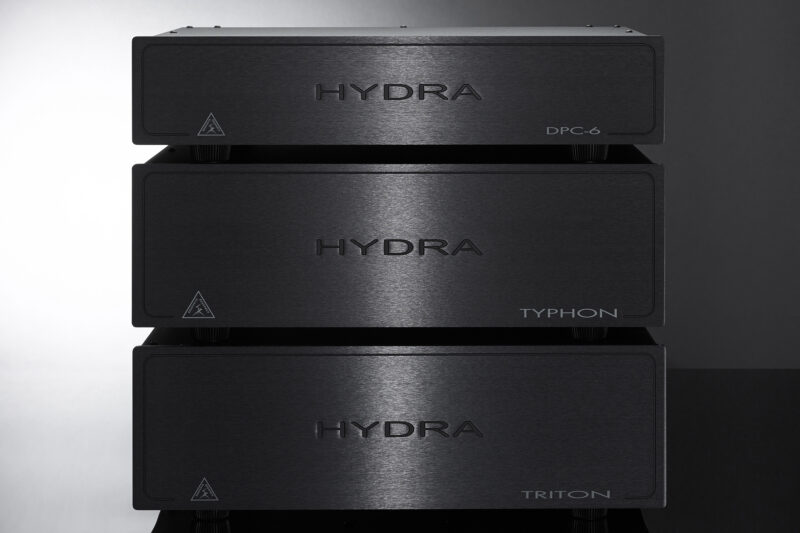

• Performance increase is comparable to or slightly above the award winning Hydra Denali 6000/S v2

Upgrade cost $1500 USD

PERFORMANCE FEATURES

VERTICAL DESIGN

The DENALI tower models are uniquely vertically- oriented. The narrow front profile allows the DENALI to be placed alongside an audio rack without taking up valuable shelf space. The close proximity to the audio equipment allows for shorter and tidier AC power cable routing. They are self supporting with an integrated isolation base platform.

INTEGRATED ISOLATION PLATFORM

The DENALI tower models include an integrated isolation base. Outriggers extend from the elegantly carved aluminum platform to provide maximum stability. Precision machined 50mm stainless steel footers create added support and dampen vibration.

CABLE CRADLE SUPPORT SYSTEM

Shunyata Research introduces a unique solution for the problem of heavy high-end power cables. The innovative Cable Cradle supports the weight of the power cable, preventing it from pulling away from the outlet, ensuring reliable electrical connections.

HIGH CURRENT CAPABILITY

The DENALI Series conditioners are designed using DTCD® analysis and carry a 20-Amp continuous rating for virtually unlimited power delivery capability allowing them to power entire systems including high powered amplifiers. The non current-limiting electromagnetic breakers combined with massive 8 gauge internal wiring maximizes instantaneous current delivery which maximizes dynamic contrast and bass impact.

EXCLUSIVE PARTS & TREATMENTS

CopperCONN® OUTLETS

Shunyata Research manufacturers its own audiophile-grade AC outlets. The internal contacts are made from pure OFE copper providing the highest level of conductivity with the least amount of electrical resistance. There is no better outlet in the industry.

ArNi® CONDUCTORS

The DENALI is wired with Shunyata Research’s ArNi® conductors. These conductors are “hollow tube” VTX™ designs that are made from pure OFE C10100 copper and then treated with the KPIP™ Processor.

KPIP™ “BLACKBIRD” PROCESSOR

Each DENALI is treated with Shunyata Research’s proprietary KPIP™ Processor. The ‘Kinetic Phase Inversion Process’ dramatically reduces burn-in time and significantly improves sonic performance.

CRYOGENIC TREATMENT

Many of the electrical parts in the DENALI are treated in Shunyata Research’s own advanced computer controlled cryogenics lab.

VIBRATION CONTROL

Mechanical vibration can be very destructive to system performance. The DENALI was designed from its inception to include advanced forms of vibration control that improve the recovery of subtle musical detail and nuance. All chassis panels and internal structure are treated with vibration dampening panels. Each outlet is isolated from the chassis with a vibration dampening gasket that reduces vibration conducted through the AC cables. All internal modules, filters and electronics are encapsulated in a vibration absorbent compound.

TECHNOLOGY

The NIC™ is a proprietary technology using ferroelectric substances that reduces high frequency power line noise. The DENALI’s next-generation NIC™ v2s have improved performance efficiency and yet are smaller in size.

Patent No. US 8,658,892

CCI™ v3 modules isolate power line noise from one component to another component. These new CCI™ modules were originally developed in our military, scientific and medical imaging research programs. They are currently being used to great effect in Electrophysiology heart surgery. CCI™ interference levels can be reduced more than -60dB from 500 KHz to 10 MHz!

New QR/BB™ technology dramatically eliminates any sense of dynamic compression that is often heard when an amplifier is connected to a power conditioner. Dynamics are actually improved when an amplifier is connected to the DENALI even when compared to a direct connection to the wall outlet.

~ Patented ~

SPECIFICATIONS

|

Input / Output Voltage: Over Current Protection: Hydraulic electromagnetic breaker Sockets / Connectors: Technology: Construction: |

Current Ratings: Transient Suppression: Wiring System: Noise Suppression: Inlet to Z1 or Z2 Inlet to Z3 (HC) Dimensions: |

OUR ASSURANCES

RELIABILITY

Over more than 2 decades, the reliability and durability of Shunyata Research products has become a legendary attribute of the brand. Shunyata products are completely non-reactive and run cool to the touch. They do not hum, vibrate, buzz, or generate heat and do not require any ventilation. Despite heavy-use applications in studios, medical labs, and home environments, Shunyata Research products maintain an almost zero failure rate.

QUALITY

In an era of products that are mass-produced, Shunyata Research invests in training career craftsman who build our products by hand at our factory in Poulsbo, Washington. The exceptional fit, finish, and attention to detail has become a hallmark trait of Shunyata Research products going back to its inception in 1998. Shunyata Research has been building some of the finest power and cable products in the industry for more than twenty years. The commitment to building durable products that are designed to last a lifetime elevates our products to the top of their class.

SAFETY

Safety and quality control is job one at Shunyata Research. Before anything leaves the factory, we test each and every product thoroughly and carefully for safety and quality. This explains the long-term success of Shunyata Research products in the professional recording, medical, scientific, and consumer industries. Shunyata Research’s impeccable product safety and reliability track record for the past 23 years speaks for itself.

NO HUM — NO BUZZ — NO HEAT

LIMITED LIFETIME WARRANTY