Please contact your authorized Shunyata Research dealer or regional distributor for pricing.

25 YEARS OF EXPERIENCE & SCIENTIFIC INNOVATION

DESIGN PROGRESSION

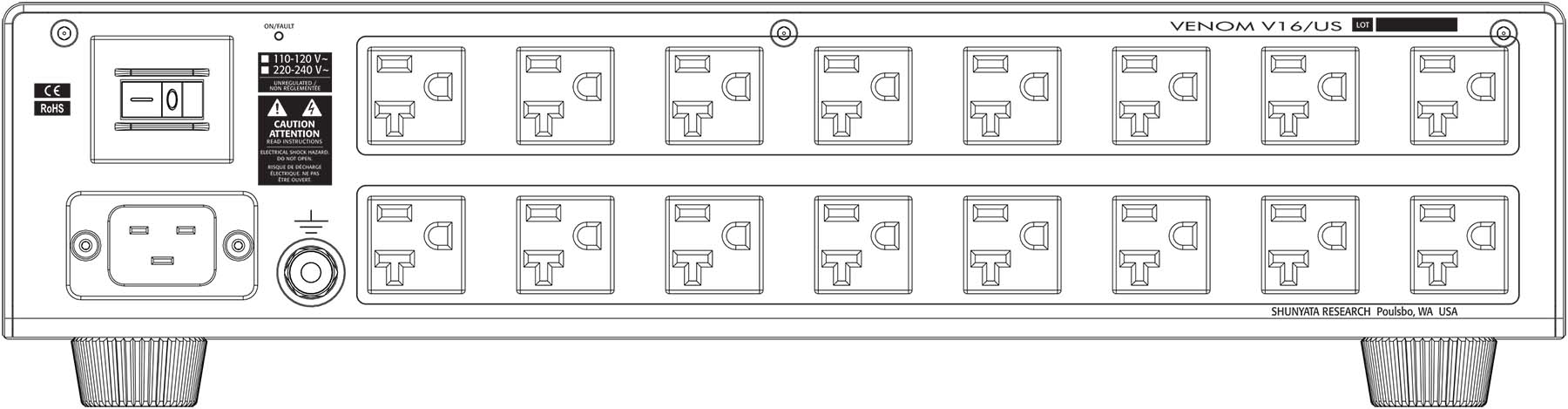

The Venom Series V16 was designed using Shunyata Research’s latest advances in dynamic transient current delivery, CCI noise reduction and vibration management. It includes many of the features of our more expensive, award winning power conditioners and yet it is very attractively priced.

The Venom Series V16’s proprietary noise reduction technology and exceptional 16 outlet capacity make it an ideal choice for home theater or complex music systems. The Venom V16’s technology and exceptional build quality provides a level of performance that is frankly unavailable from products priced two to three times higher.

There is no better example of Shunyata Research’s meteoric achievements in performance and value than that provided by the Venom Series V16 power distributor.

Customers Agree

“The Shunyata Venom Series V16 makes a large and noticeable improvement in both sound and video. I would rank it just behind the dCS Bartok in making everything sound better… cleaner bass, better soundstage, and just overall noticeable improvement in sound. It just seems to allow all the other components to reach their full potential.”

“Music flows as though without restriction. Bass is laser focused and its thunderous growl no longer affects the mid bass or mid-range. The vocals become more in focus and life-like. Minute minutiae hidden within the folds of sound come creeping out as if awakened from a deep sleep. The timing of notes are precise and exact as is the attack and decay. The notes meet each other as the layers of instruments come together in a sea of sound. This is a stereo setup but music appears behind me, off to the sides of the speakers and in front of me; even if I move left or right.

Astonishing that the price of admission to this world is the Shunyata Venom V16 and the Delta XC. “

APPLICATIONS

— Perfect for home theater or complex audio-video systems —

TECHNOLOGY

DUAL ISOLATION ZONES

The Venom V16 is rated for a full 20-amps of continuous current allowing it to handle very demanding home theater systems, including multiple high power amplifiers. It features two independent noise reduction isolation zones, each with an eight outlet array. This allows for partitioning between source or application use. For example, use Zone A for digital and Zone B for analog in a home audio system or Zone A for visual and Zone B for audio equipment in a home theater system. This versatility offers unprecedented control in noise reduction capabilities at an astonishing value.

CCI™ NOISE REDUCTION

Traditional power conditioners are designed to block incoming noise from outside the home, but do not address the noise that is generated by the electronic components themselves. In fact, most conditioners reflect noise back into other components connected to the power conditioner. CCI™ (Component-to-Component Isolation) is one of the most significant but often overlooked aspects to power system performance. The CCI™ filter consists of a proprietary multi-stage filter that reduces electrical noise and interference generated by a component’s power supply.

ArNi® Conductors

Shunyata Research’s ArNi® conductors are designed to be the finest quality wire available for power and audio purposes. They start life using the highest purity copper available – OFE C10100 (or Ohno single crystal). Then they are formed into “virtual hollow tubes” that we call VTX™. The core of the conductor is completely hollow forcing the current to only travel through the periphery of the conductor, therby eliminating skin effects and random eddy currents.

And finally, every ArNi® wire undergoes our proprietary KPIP™ process.

Electromagnetic Breaker

Over-current protection is a requirement for today’s high current audio power distributors. The vast majority of manufacturers use an inexpensive thermal fuse or breaker. Both are specifically designed to heat up as the current level rises. This causes voltage drops, increased contact impedance, thermal noise, excessive heat generation and current limiting effects. There is a better solution — the hydraulic electromagnetic breaker that utilizes low-impedance relays and a sensing coil that reads the current level without heating up or limiting current. They can operate right up the to the maximum current level without heating up or limiting instantaneous current. They are rarely used in competitive products since they cost 10-20 times that of a common fuse or thermal breaker.

After years of research into the negative effects of vibration, Shunyata Research developed its own vibration isolation using sub-miniature accelerometers that accurately measure the effects of floor and airborne sound waves. We use it in the development of vibration absorbing materials such as energy absorbing footers, AC outlet gaskets and chassis dampeners that reduce resonant vibration. Recognizing that vibration control is important to overall performance, our chassis are made with optimally dampened steel and aluminum, rather than plastic or thin-wall sheet metals.

KPIP v2™ Shunyata Research’s proprietary Kinetic Phase Inversion Process includes four days of continuous KPIP v2™ processing which refines conductor metals at the atomic level. This dramatically reduces burn-in time and significantly improves sonic performance, delivering a relaxed and life-like presentation. When compared to the original process, KPIP v2™ represents a dramatic performance upgrade on par with a component-level upgrade.

Sonic Welding

Simple crimping, soldering, brazing and screws are all inferior methods of joining two wires or terminals together. Sonic welding uses high-energy sonic waves to literally join two metals together at a molecular level and cold-welding uses high-energy pneumatic pressure to bond metals. Shunyata Research uses both methods to secure connections that do not degrade over time.

Cryogenic Processing

Shunyata Research operates its own onsite Cryogenics International computer-controlled cryogenic plant. Liquid nitrogen is used to reduce the temperature of the contents to -320 degrees Fahrenheit. The computer monitors and lowers the temperature by a single degree at a time to prevent thermal shock.

We use this process to improve the performance of connectors and various electrical components that are used in our power products and signal cabling.

SPECIFICATIONS

|

Maximum Voltage: Input Current Ratings: Output Current Ratings: Transient Suppression: Over-Current Protection: Wiring System: Noise Suppression: |

Isolation Zones: 2 zones Outlets & Connectors: US Outlets: 16 NEMA5-20R KPIP v2 Processing: 4-days Vibration Control: Construction: Dimensions: |

OUR ASSURANCES

RELIABILITY

Over more than 2 decades, the reliability and durability of Shunyata Research products has become a legendary attribute of the brand. Shunyata products are completely non-reactive and run cool to the touch. They do not hum, vibrate, buzz, or generate heat and do not require any ventilation. Despite heavy-use applications in studios, medical labs, and home environments, Shunyata Research products maintain an almost zero failure rate.

QUALITY

In an era of products that are mass-produced, Shunyata Research invests in training career craftsman who build our products by hand at our factory in Poulsbo, Washington. The exceptional fit, finish, and attention to detail has become a hallmark trait of Shunyata Research products going back to its inception in 1998. Shunyata Research has been building some of the finest power and cable products in the industry for more than twenty years. The commitment to building durable products that are designed to last a lifetime elevates our products to the top of their class.

SAFETY

Safety and quality control is job one at Shunyata Research. Before anything leaves the factory, we test each and every product thoroughly and carefully for safety and quality. This explains the long-term success of Shunyata Research products in the professional recording, medical, scientific, and consumer industries. Shunyata Research’s impeccable product safety and reliability track record for the past 23 years speaks for itself.

NO HUM — NO BUZZ — NO HEAT

LIMITED LIFETIME WARRANTY