Please contact your authorized Shunyata Research dealer or regional distributor for pricing.

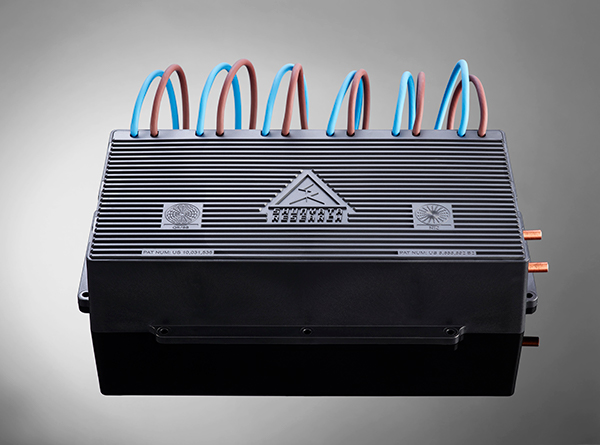

TRANSFORMATIONAL HIGH-CURRENT PERFORMANCE

TECHNOLOGY

DYNAMIC TRANSIENT CURRENT DELIVERY

DTCD™ Analysis is a technique that measures instantaneous current through low impedance electrical conductors and contacts. Shunyata Research uses it to optimize the design, specification and construction of parts and materials to ensure maximum current delivery performance. Each part, conductor, noise circuit and material allows for maximum throughput of instantaneous current.

Listeners will experience earth-shaking low-frequency performance from even the highest-current amplifiers as well as dynamic contrasts unheard of outside of a live event. More than any other design parameter, Shunyata Research’s skill in eliminating resistance and maximizing peak-current delivery is unmatched.

QR/BB™ TECHNOLOGY

The QR/BB™ module possesses the ability to act as an electric charge reservoir, meaning it stores and releases energy in a manner that improves a component’s access to instantaneous current.

Dynamics are actually improved reducing any sense of dynamic strain often heard from amplifiers that are connected with lesser power cables.

The sonic result is a lifelike presentation of timing and dynamic contrasts in sound that cannot be replicated by ANY other means. In layman’s terms, it acts like a super-charger for amplifiers, pre-amps, DACs and CD players.

— Patent Number: US 10,031,536 —

CCI™ NOISE REDUCTION

Traditional power conditioners are designed to block incoming noise from outside the home, but do not address the noise that is generated by the electronic components themselves. In fact, most conditioners reflect noise back into other components connected to the power conditioner. CCI™ (Component-to-Component Isolation) is one of the most significant but often overlooked aspects to power system performance. The CCI™ filter consists of a proprietary multi-stage filter that reduces electrical noise and interference generated by a component’s power supply.

NIC™ TECHNOLOGY

The NIC™ (Noise Isolation Chamber) is a patented technology that reduces high frequency power line noise.

NICs™ use a non-reactive ferroelectric substance that actually absorbs high frequency noise. This reduces noise without any of the negatives associated with power filter coils, capacitors and transformers.

— Patent Number: US 8,658,892 —

The NIC™ (Noise Isolation Chamber) is a patented Shunyata Research device that reduces high frequency power line noise. It employs a ferroelectric substance that actually absorbs high frequency noise without any of the reactive negatives associated with transformers and large capacitors as used in conventional power conditioners.

~ Patent US 8,658,892 ~

KPIP v2™ Shunyata Research’s proprietary Kinetic Phase Inversion Process includes four days of continuous KPIP v2™ processing which refines conductor metals at the atomic level. This dramatically reduces burn-in time and significantly improves sonic performance, delivering a relaxed and life-like presentation. When compared to the original process, KPIP v2™ represents a dramatic performance upgrade on par with a component-level upgrade.

MONOLITHIC CONSTRUCTION

One of our fundamental design imperatives is to ensure life-long performance and durability. Long-term exposure to air can oxidize and corrode wiring and sensitive electronic components. All of the filters, PCBs, connections and internal wiring are contained within a monolithic enclosure and then potted with ceramic materials that hermetically seal the contents. This protects the circuits and wiring from humidity and oxidation, and eliminates internal vibration between components. This unique construction methodology delivers exceptional and consistent performance that will not degrade over time.

ArNi® Conductors

Shunyata Research’s ArNi® conductors are designed to be the finest quality wire available for power and audio purposes. They start life using the highest purity copper available – OFE C10100 (or Ohno single crystal). Then they are formed into “virtual hollow tubes” that we call VTX™. The core of the conductor is completely hollow forcing the current to only travel through the periphery of the conductor, therby eliminating skin effects and random eddy currents.

And finally, every ArNi® wire undergoes our proprietary KPIP™ process.

Many audiophile grade connectors are made from brass or bronze. While some may get a plating of silver, gold or rhodium, the majority of the current is carried by the contact’s base-metal. CopperCONN® connectors contain pure copper contacts which have a much higher conductivity than brass. The difference in performance is clearly audible.

The CGS (Chassis Grounding System) is an internal ground-buss that uses patented NIC™ technology to reduce ground plane noise. CGS provides a common grounding point and extends the noise reduction capability of the power conditioner’s internal NICs to other electronic components. CGS helps to minimize inter-component voltage differences between component chassis and may reduce the hum associated with ground loops.

SPECIFICATIONS

|

Maximum Voltage: Input Current Ratings: Output Current Ratings: Transient Suppression: Over-Current Protection: Wiring System: Noise Suppression: |

Connectors & Sockets: KPIP v2 Processing: 4-days Isolation Zones: Vibration Control: Construction: Dimensions: |

OUR ASSURANCES

RELIABILITY

Over more than 2 decades, the reliability and durability of Shunyata Research products has become a legendary attribute of the brand. Shunyata products are completely non-reactive and run cool to the touch. They do not hum, vibrate, buzz, or generate heat and do not require any ventilation. Despite heavy-use applications in studios, medical labs, and home environments, Shunyata Research products maintain an almost zero failure rate.

QUALITY

In an era of products that are mass-produced, Shunyata Research invests in training career craftsman who build our products by hand at our factory in Poulsbo, Washington. The exceptional fit, finish, and attention to detail has become a hallmark trait of Shunyata Research products going back to its inception in 1998. Shunyata Research has been building some of the finest power and cable products in the industry for more than twenty years. The commitment to building durable products that are designed to last a lifetime elevates our products to the top of their class.

SAFETY

Safety and quality control is job one at Shunyata Research. Before anything leaves the factory, we test each and every product thoroughly and carefully for safety and quality. This explains the long-term success of Shunyata Research products in the professional recording, medical, scientific, and consumer industries. Shunyata Research’s impeccable product safety and reliability track record for the past 23 years speaks for itself.

NO HUM — NO BUZZ — NO HEAT

LIMITED LIFETIME WARRANTY